Highway Guardrail

Highway Guardrails is a system designed to keep people or vehicles from straying into dangerous or off-limits areas. In traffic engineering, guardrails prevent vehicles from veering off the roadway into oncoming traffic, crashing against solid objects or falling into a ravine. A secondary objective is keeping the vehicle upright while deflected along the guardrail.

Application of highway guardrail

our highway guardrail can be seen everywhere in our lives, not only in the expressway, but also in the industry, such as factories, workshops, warehouses, parking lots, commercial areas, public places and other occasions to protect and protect equipment and facilities.

Guardrails are made of steel, such as round steel tubes, square steel tubes or profiled steel sheets. Surface treatment process: galvanized or sprayed. The guardrail has a beautiful appearance and is not easy to rust.

The guardrail effectively reduces the damage of equipment and facilities caused by accidental impact during the shuttle transportation, and also plays a protective role for the logistics handling equipment itself, such as the protective fence on the edge of the loading and unloading platform to prevent the accidental fall of the forklift truck.

Our company's export guardrails have various specifications to meet all kinds of needs. Our highway guardrail have been exported to various countries and made contributions to public infrastructure construction.

Standard of high quality guardrail

Highway Guardrail Material Property

The properties of steel mainly refer to mechanical properties, which can be divided into strength, plasticity and impact toughness. Strength performance indicates resistance to plastic deformation and failure of steel, including elastic limit, yield limit, strength limit, fatigue limit and hardness. Plasticity indicates the plastic deformation capacity of steel, including elongation. Area reduction and cold-bending. Impact toughness indicates the resistance of steel to impact load. As the content of various components in the material affects the mechanical properties of the steel, the properties of the raw material include chemical analysis, tensile test and bending test. If the guardrail manufacturer provides the quality certificate issued by the manufacturer, only the tensile test will be carried out.

Hot dip galvanized for Highway Guardrail

In order to ensure its anticorrosion performance, all the parts of the highway guardrail are generally treated by hot dip galvanizing. In order to ensure its anti-corrosion performance, it is necessary to detect the adhesion of galvanized layer, the uniformity of galvanized layer and the adhesion property of the galvanized layer in three aspects.

adhesion galvanized layer of Highway Guardrail

The zinc used for dip galvanizing should be 0 zinc or 1 Zinc specified in GB470, zinc content and Zine plating thickness.The provisions of table 2-13

The test of zinc adhesion can be tested by three antimony chloride or coating thickness gauge. Three the basic principle of antimony chloride method: because zinc can completely dissolve in the concentrated hydrochloric acid solution of three antimony chloride, the amount of zinc adhesion per unit area is calculated by weighing two times before and after dissolving.

Galvanizing adhesion of components:

| Component name | Average zinc attachment (g/m2) | Minimum zinc attachment (g/m2) | Average thickness of zinc layer(mm) | Minimum thickness of zinc layer (mm) |

| Highway guardrail,end terminal,post | 600 | 425 | ≥85 | ≥61 |

| fasten, spacer, bracket | 350 | 275 | ≥50 | ≥39 |

Our highway guardrail advantage

Materials: all of our materials are purchased from regular steel mills, with factory certification, and our highway guardrail has passed CE certification.

Zinc plating: our galvanized content is 550g/, zinc content is in line with international standards, high corrosion resistance.

Standard: the highway guardrail has a complete set of moulds, and the guardrail produced is in line with the AASHTO M180 Standard.

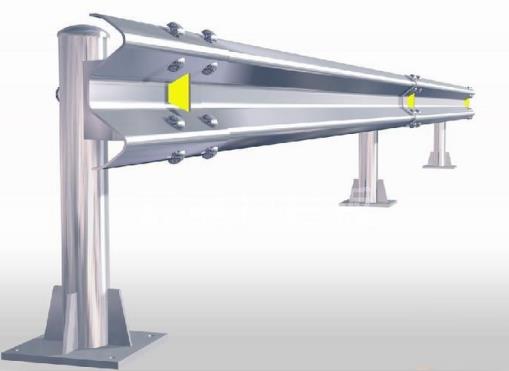

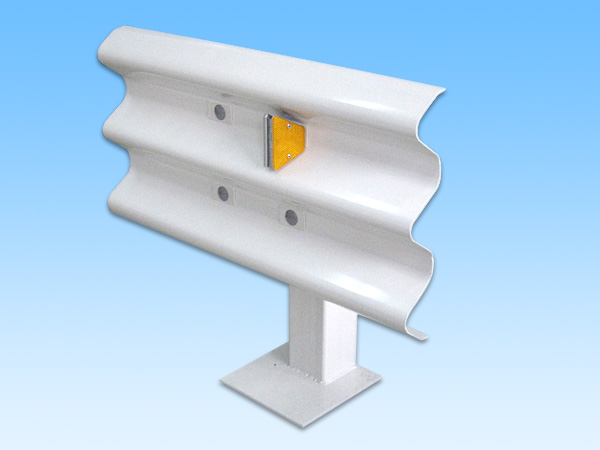

Highway Guardrail Products

We are the China's premier supplier of Highway Guardrail and Highway Safety Equipment!

How to install the guardrail

Our company has a professional construction team and can be installed at the project site. The technical personnel of the construction site survey the site carefully, carry out the necessary leveling on the construction site, then complete the measurement and set out the sample, and start the installation of the wave beam facilities after all the readiness is ready, and the concrete plan is as follows:

Before the construction is ready, the construction technicians are familiar with, understand the design drawings and related construction specifications, and check with the constructors to the construction site and the design drawings to find out the number of the pile, the various structures and the setting of the structure guardrails.

1)The post layout of steel guardrail

The vertical post should be set out according to the design drawings, and take the bridge, channel, culvert, interchange and flat intersection as control points to locate the distance, adjust the distance by the adjustment section, and use the distribution method to deal with the number of spacing.

In order to accurately loft and ensure the alignment of the guardrail, pile number is checked and closed.

After the post is set out, the surface state of each column should be investigated. In case of underground communication pipeline, discharge, or insufficient buried depth at the top of the culvert, the position of some columns should be adjusted to change the fixed style of the post.

highway safety components

we can supply different types of highway guardrail components,the accessories can be with the AASHTO 180 standard.

2)Steel highway guardrail post installation

Drill the column according to the design drawings and check the alignment with the road alignment.

If the basic condition of the shoulder is allowed, the pile should be set up by the method of entry, and the construction should be accurately positioned. The column should be buried in the soil to the design depth. When it is too deep, the column should not be pulled out to be corrected, but all of it must be pulled out to be replayed after the foundation is compacted.

When the post is difficult to enter, it can be installed by drilling or excavation. After the installation of the drilling method, the post should be filled with the same material as the Subgrade after the post positioning, and compacted with the layered ramming. The excavation method is used to bury the column. The backfill soil should be made of good material and rammed (the thickness of each layer is not more than 15cm). The compaction degree of the backfill should not be less than that of the adjacent original soil.

The guardrail post installed in the construction is generally constructed on the concrete foundation during construction. When using the reserved hole foundation, we should clear the hole in the hole first, absorb the water in the hole, and apply the good bitumen to the bottom of the hole, then put it in the column to control the elevation. Sand can be injected around the column. When pouring sand, the correct position and perpendicularity of the column must be maintained. After the sand is vibrated, it can be sealed with asphalt to prevent rainwater from leaking into the hole.

In the construction of the column of the asphalt pavement, the 5cm of the column pit from the subgrade to the surface layer is backfilled and rammed with the same material as the subgrade. The remaining part is backfilled and rammed with the same material as the pavement.

When the post is installed, it forms a smooth alignment in horizontal and vertical directions.

In the construction of the end guardrail of the gradual change section, the position of the column should be strictly controlled according to the design coordinate.

3) W beam guardrail installation

When the wave beam is installed, the splicing bolts are mutually spliced together, and the connecting bolts are fixed on the columns or beams. The direction of wave beam splicing is the key to installation. During construction, the lap direction should be consistent with the direction of traffic.

The wave beam should be adjusted continuously during the installation process, so the connecting bolt and splice bolt should not be tightened too early so as to make use of the long circular hole of the wave beam to adjust it in time so that it can form a smooth line form and avoid the local concave and convex.

The top surface of the corrugated beam should be coordinated with the vertical curve of the road when installed. And check the alignment of the guardrail. When the alignment is straight and smooth, the bolt can be tightened later.

4) highway guardrail spacer installation

highway guardrail spacer can prevent the post from blocking the wheel, avoid the partial force of the guardrail and slow down the vehicle when the collision is collided. Therefore, it should be ensured to be in position accurately. Before the installation and adjustment, the anti blocking block can be installed.

The resistance block is fixed between Yu Lizhu by the connecting bolt, and the wave beam is installed and 5, the wave beam steel guardrail is installed and the terminal head is installed. Terminal beam should be installed at the opening of roadside guardrail and anchored. The end anchorage mainly includes wire rope anchor and concrete foundation. After the design strength of the end base concrete reaches 50%, the bolt or fixed cable can be tightened.

The movable steel guardrail is installed at the opening of the movable steel fence in the central section, which is installed after the installation of the wave beam steel guardrail. Before the construction and installation, according to the requirements of the design documents, the installation position and quantity of the movable steel guardrail should be checked and checked; the installation should be carried out according to the fixed position.

The installation should be vertical to the ground, the longitudinal shape is suitable, no concave or convex or twisted. The base bushing is embedded in advance. After installation, it should be tested whether it is easy to pull out and re insert. Make a unified adjustment.

highway guardrail installation attention

①The construction preparation should be adequate, and the location of pile numbers in construction sections should be accurately located. The setting out should be accurate and the error is within the specified scope.

②The vertical post construction should be strictly careful, its perpendicularity, spacing, bolt hole position and other dimensions should meet the requirements, not meet the requirements of immediate rework. At the same time, the rework should be carried out in strict accordance with the regulations of JTJ074-94.

③The packaging and marking of components such as corrugated beam, column and so on shall conform to the requirements of GB6725. The guardrail shall not be packed in bulk, and shall ensure that the product is not damaged or damaged during lifting, transportation and stacking. The transportation process should be fixed and reliable so as to prevent the bumps from damaging the coating or the deformation of the components.

④Attention should be paid to packing and marking of bolted high-strength splicing bolts at the time of purchase, in accordance with the relevant provisions of GB/T1231.

⑤During the construction of guardrail, caution should be taken in the construction of the fence, not to destroy the cables, pipelines and other facilities laid under the road surface.

why choose us?

1. We have more than 20 years of experience in the production of highway guardrail, and our products are exported to many countries.

1)We have worked with Brazil customers for three years, and Brazil customers have applied the guardrail produced by us to the highway construction in their country.

2)We have worked with Australian customers for five years. Australian customers mainly use infrastructure, such as parking lots, airports and warehouses. Because of our good quality and competitive price, we have been recognized by our customers.

3)In cooperation with New Zealand customers, customers are mainly used for highway repair. A bad guardrail is changed.

2. It can be produced according to the drawings of the customers. Orders are flexible, large orders, small quantities of orders can be produced.

3. Professional logistics team. A system has been formed from procurement, production and shipment